Managing Director

Tech and Sales

Mobil: +49 7231 397 238 – 0

e-mail: ralf.kaufmann@conectronics.de

Conectronics offers a wide range of standard solutions,

that are available in large and small quantities.

We guarantee a long-term availability of 10 jears +

We also specialize in drop-in replacements,

Alternatives to renowed manufacturers that meet all quality standards

The savings potential of drop-in replacements can be significant.

We are talking about high-quality replacements for standart parts of well-known manufacturres.

The matching pars are made available via our sample service.

What we can:

We solve their task because we understand something about it.

That`s why our suggestions are rated as best as possible for technical feasibility and manufacturability.

Your product soluton is examined with regard to oppurtunities, benefits costs and risks.

Product design, toolmaking and process development are clear thanks to our expertise, so we avoid recursion loops and “surprises”.

Our technology focus is injecton moulding, stamping technology and cable assembly.

We already set quality standards when we are findin a solution. Thats why we always provide you with the best quality with ISO-certification.

1. DISCOVER

2. DEFINE

3. DESIGN

4. DELIVER

5. DISTRIBUTE

Our systematic way of working in connection with relevant expertise helps our customers to plan in a structured, effective and efficient manner.

Conectronics thinks sytematically- and always thinks of the best solution for you.

We develop quality with ISO- certification

We develop prototypes using different digital processes. This is how we minimize any risks later in production.

Development in 3D, up to quality assurance manufacturing.

Special construction in order to be able to deliver the required quantites in a cost-saving manner.

Development in 3D, up to quality assurance manufacturing.

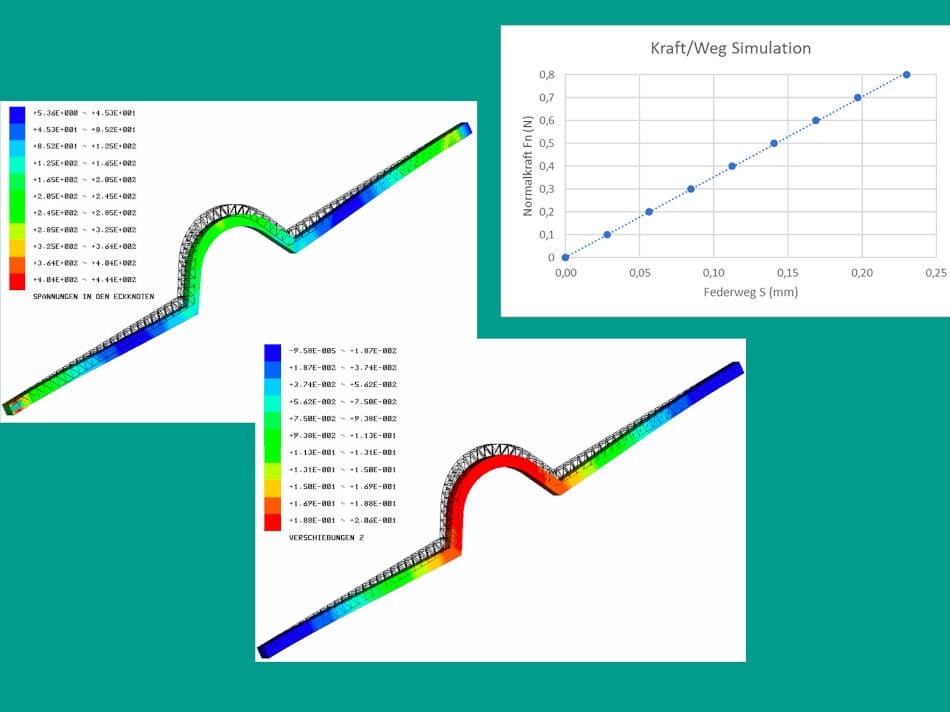

Simulation results of a spring contact etched after optimization

Despite previous calculations, the contacts in the FEM simulation showed excessive node stresses, regardless of the simulation method (Von Mises, Rankine, Tresca).

With one-sided clamping, a special material would be required and, in addition, a greater material thickness. Both would have a negative impact on etch feasibility and availability. The spring concept was therefore changed.

In addition to being clamped on one side, the contact is supported on the other side of the contact. The length of the contact leg is optimized. This enables a normal contact force of approx. 0.7 N with a spring deflection of approx. 0.2 mm, with CuSn6 R500 with a thickness of 0.2 mm. With approx. D=3.5 N/mm, the spring constant is “soft” enough to be able to compensate for tolerances.

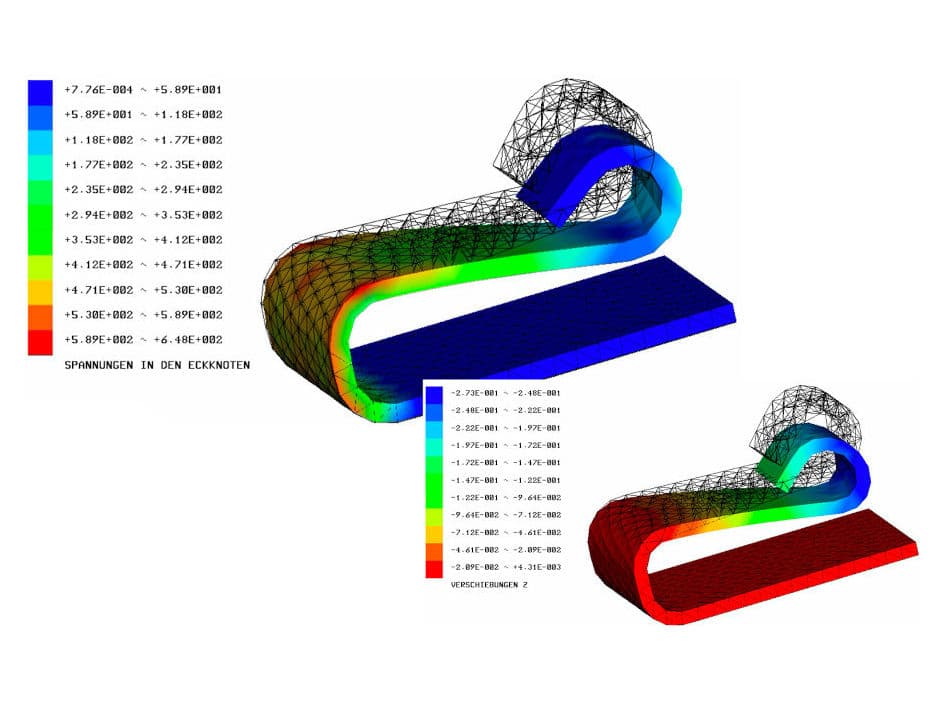

Bracket2 (picture)The initial spring concept had to be changed by the assembler due to availability and processability. A special material was used in order not to exceed the permissible material stresses in the available space.

The images show an example of 0.26 mm displacement and 0.7 N force with 0.8 mm thick CuBe2 and one of a total of 13 different simulated geometries. The spring constant here is approx. D=2.67 N/mm.

Qualified contact persons

Open and personal cooperation

We make sure that you receive the delivery exactly on the day when you really need the goods. This saves you storage and you have the order available at the optimal time for your processes.

We guarantee you long- term availabiliy. On special request we can provide you with long-term storage in nitrogen.

Delivery as required.

For SMT / High Temperature-Applications we supply the approbiate reel or Tape.